In the early 1950s, Japan’s industries were struggling to recover from the post-war years. Toyota, then a small automaker, couldn’t afford to buy parts in bulk or keep large inventories like its American counterparts, Ford and GM.

Their procurement team faced a brutal question: how could they keep production running with minimal inventory without stopping the lines?

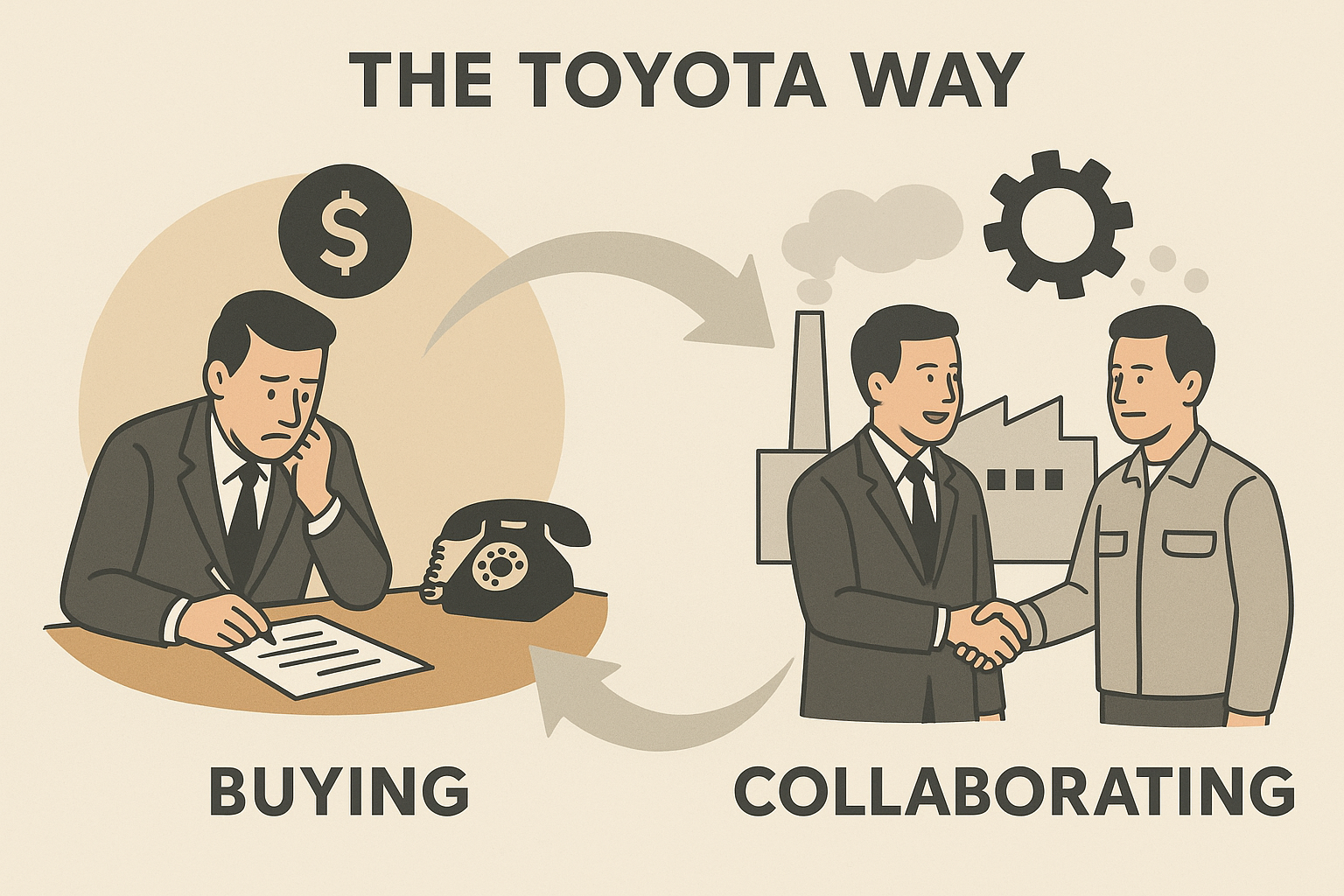

They came up with a brilliant idea: their procurement team, led by Taiichi Ohno and Kiichiro Toyoda, began collaborating with suppliers rather than just buying from them. They shared forecasts, synchronised deliveries, and helped suppliers improve quality and efficiency.

Their collaboration gave birth to two revolutionary ideas:

Just-in-Time (JIT) — materials arrive only when needed

Kanban system — a visual signal to trigger replenishment

Instead of pressuring suppliers for the lowest price, Toyota’s procurement focused on mutual growth and waste elimination — an idea ahead of its time.

The results were astonishing. By 1970, Toyota’s supplier network had become one of the most efficient ecosystems in the world. When the oil crisis hit, Western automakers struggled; Toyota thrived — because its suppliers were agile, informed, and deeply integrated.

That shift — from buying to partnering — completely redefined procurement. It’s the root of what we now call Supplier Relationship Management (SRM) and Lean Supply Chain.

The world is at the crossroads once again, what with tariffs and disrupted supply chains.

Is your procurement team up to the task?

And just like Toyota’s philosophy, at TrustX, we treat you like a partner, not as a purchaser.

Trustx specializes in navigating its dynamic market to deliver high-quality, cost-effective sourcing opportunities

© Copyright 2025 | Trustx Sourcing | All right reserved.